TEC-250

652Vertical Motor Drive Wheel Unit TEC-250

DetailsSite Search

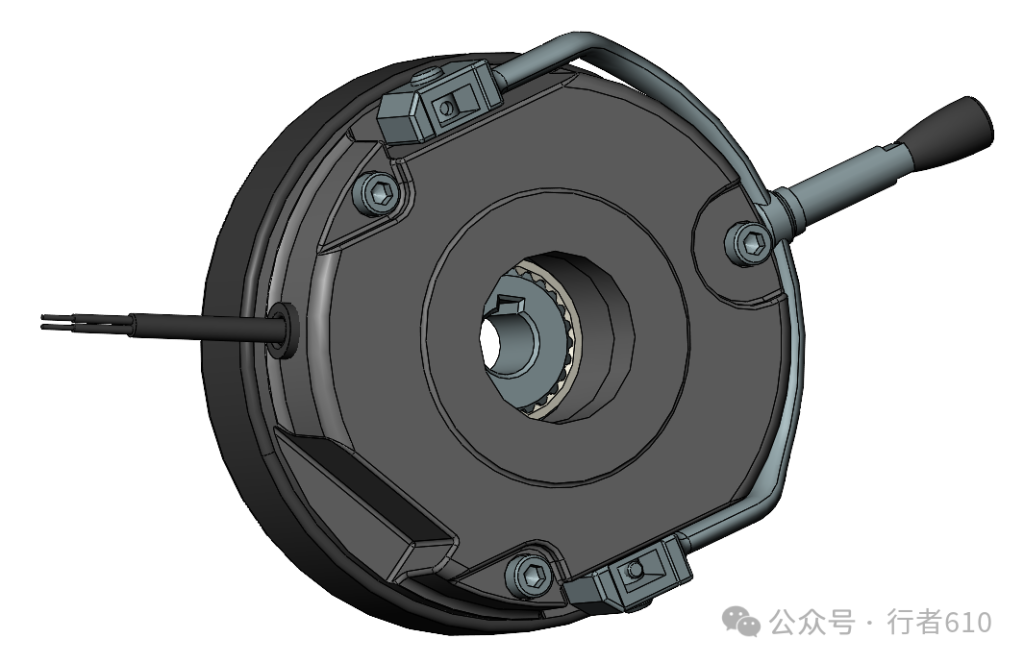

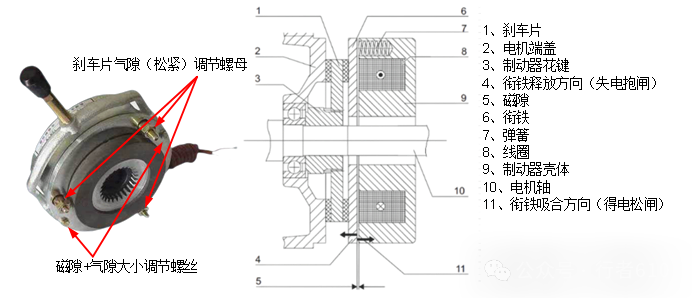

With the explosive development of the AGV industry, fail-safe electromagnetic brakes are widely used on AGVs to ensure safety. These brakes, also known as holding brakes, are the focus of this article, which discusses common faults, their causes, and installation and adjustment tips. The working principle of fail-safe electromagnetic brakes is that when the brake coil is powered, the armature releases the friction plates, allowing the motor shaft to rotate freely. In the event of an emergency stop or to prevent the AGV from rolling back, power is removed from the coil, causing the friction plates to be pressed and held by springs, locking the drive shaft in place.

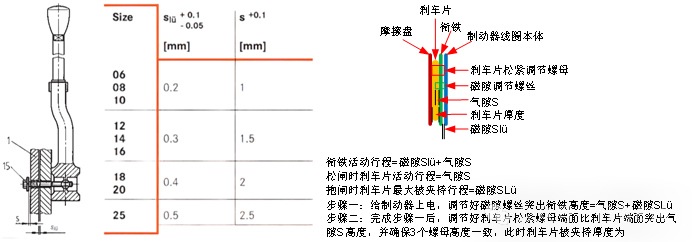

As shown in the diagram, the electromagnetic brake consists of both electrical and mechanical components, so this article addresses faults and correct handling methods from both perspectives. A normal brake coil has a relatively low resistance. The resistance values of coils vary based on different power levels (or braking torque), typically ranging from several tens to hundreds of ohms. After disconnecting from the external circuit, a multimeter can be used to measure its resistance. If the resistance falls within this range, the coil is likely normal; an open or short circuit indicates a fault. Most brakes used in AGVs operate on low-voltage DC power, such as 24VDC, 48VDC, or 72VDC. The supply voltage and current must be adequate for normal operation, enabling the generation of sufficient electromagnetic force to fully release the armature.

While the symptoms of brake malfunctions can be complex, understanding the working principle allows for quick identification of issues. With proper adjustment and installation techniques, normal operation can be restored.

Yikong will participate in the 2024 CeMAT Russia logistics exhibition! Venue:ICE Crocus Expo Exhibition Dates:Sep 17th -Sep 19th 2024 Booth:Hall2,B109 CeMAT Russia logistics exhibition is the most influential...

DetailsThis website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies.

Data collected from this website is processed and stored in the United States.

See Our Privacy Policy

Hello!Please login